Where Innovation and Collaboration Unite

Seco Tools’ innovation partnership manager explains how a collaborative partnership between Seco and CGTech provides a resultant force.

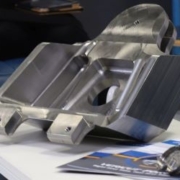

A collaborative partnership between cutting tool technologies specialist, Seco Tools, and leading independent CNC simulation and optimisation software provider, CGTech, is harnessing exceptional results for even the most demanding of customers.

David Magnall, Seco Tools’ innovation partnership manager, recalls: “At the time there was no true collaboration. However, we started to recognise that customers wanted more. As engineering departments have been whittled down and down, large businesses expect their suppliers to provide technical support”.

“As a tooling supplier we can usually make an incremental change, but if we interact with other companies that are part of that manufacturing process, we can deliver improvements as a collective which is more of a holistic solution. For our event we started to engage partners to focus on actual customers issues and components. It allowed us to demonstrate what we and our partners believe to be best practice manufacturing solutions. From there the idea grew and we thought we do this once a year why can’t we do this every day?”

CGTech in partnership with Seco Tools can provide turnkey solutions for businesses looking for high efficiency gains. As Magnall points out: “Customers are looking to take at least 40% and up to 60% or more out of the manufacturing process, in terms of cycle times and therefore cost, and we need partners to achieve this. These are partnerships where we sit down at the beginning of the year and say what we want to achieve together, what can we do that is proactive rather than wait for projects to come in and highlight what we recognise in the market that needs to be addressed.”

Today’s collaborative approach builds on the history between the two businesses so they have created a method of providing more holistic process improvements for customers’ manufacturing operations.

Environmental sustainability is a huge topic within the manufacturing industry, and although people have talked about it for a long time there is now pressure to start making good and deliver.

“There are targets being set that people are working towards. Also, it’s not just the products, it is the whole manufacturing operation that needs to be more sustainable and more environmentally aware. We are certainly seeing it more and more with customers, they increasingly want to only do business with other companies that have some sort of sustainability plan in place.

Summing up the collaborative partnership, Magnall concludes: “We have a great team at Seco, and our business model is always to try to provide a one-stop shop. But we only have a finite resource and by partnering it helps us achieve the customers’ goals. We understand the collaborative approach as a proactive way of working and addressing the issues faced by industry.”