The technology could boost aerial robots’ repertoire, allowing them to operate in cramped spaces and withstand collisions.

Insects can be remarkably acrobatic and resilient in flight. Those traits help them navigate the aerial world, with all of its wind gusts, obstacles, and general uncertainty. Such traits are also hard to build into flying robots, but MIT Assistant Professor Kevin Yufeng Chen has built a system that approaches insects’ agility.

Chen, a member of the Department of Electrical Engineering and Computer Science and the Research Laboratory of Electronics, has developed insect-sized drones with unprecedented agility and resilience. The aerial robots are powered by a new class of soft actuator, which allows them to withstand the physical travails of real-world flight. Chen hopes the robots could one day aid humans by pollinating crops or performing machinery inspections in cramped spaces.

According to Chen, “The challenge of building small aerial robots is immense.” Pint-sized drones require a fundamentally different construction from larger ones. Large drones are usually powered by motors, but motors lose efficiency as you shrink them. So, Chen says, for insect-like robots “you need to look for alternatives.”

The principal alternative until now has been employing a small, rigid actuator built from piezoelectric ceramic materials. While piezoelectric ceramics allowed the first generation of tiny robots to take flight, they’re quite fragile. And that’s a problem when you’re building a robot to mimic an insect — foraging bumblebees endure a collision about once every second.

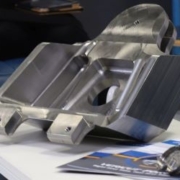

Chen designed a more resilient tiny drone using soft actuators instead of hard, fragile ones. The soft actuators are made of thin rubber cylinders coated in carbon nanotubes. When voltage is applied to the carbon nanotubes, they produce an electrostatic force that squeezes and elongates the rubber cylinder. Repeated elongation and contraction causes the drone’s wings to beat — fast.

Chen’s actuators can flap nearly 500 times per second, giving the drone insect-like resilience. “You can hit it when it’s flying, and it can recover,” says Chen. “It can also do aggressive manoeuvres like somersaults in the air.” And it weighs in at just 0.6 grams, approximately the mass of a large bumble bee.

Because of the soft actuators’ inherent compliance, the robot can safely run into obstacles without greatly inhibiting flight. This feature is well-suited for flight in cluttered, dynamic environments and could be very useful for any number of real-world applications.

Building insect-like robots can provide a window into the biology and physics of insect flight, a longstanding avenue of inquiry for researchers. Chen’s work addresses these questions through a kind of reverse engineering. His drones can also be useful in industry and agriculture.

Chen says his mini-aerialists could navigate complex machinery to ensure safety and functionality. “Think about the inspection of a turbine engine. You’d want a drone to move around with a small camera to check for cracks on the turbine plates.”

Other potential applications include artificial pollination of crops or completing search-and-rescue missions following a disaster.

Source